What we do

Anmajy specializes in custom development and scalable manufacturing of lingerie and swimwear.

We work with brands that have clear product direction and long-term plans, offering end-to-end manufacturing support from development to delivery.

Our core capabilities include:

- Lingerie Manufacturing

Including wireless bras, lace lingerie, and bonded or seamless constructions, with a strong focus on comfort and craftsmanship. - Swimwear Manufacturing

Supporting high-stretch fabrics, custom prints, and optimized structures for brand collections and commercial sales. - Shapewear & Seamless Apparel

Providing stable patterns and mature production processes for functional and scalable product lines. - OEM & ODM Manufacturing Services

From sampling and small-batch development to bulk production, best suited for brands seeking long-term manufacturing partnerships.

Rather than mass production for everyone,

Anmajy focuses on building products together with brands and supporting sustainable growth.

Who We Work With

We Work Best With Clients Who:

✔ Have clear brand positioning

From independent designers to established brands, we prefer partners with a defined market direction.

✔ Provide tech packs or are open to co-development

Including design files, reference samples, or a willingness to refine products together.

✔ Value product quality and craftsmanship

Focusing on fit, comfort, and long-term consistency rather than lowest price only.

✔ Seek long-term manufacturing partnerships

We specialize in ongoing product development and scalable production, not one-off orders.

Anmajy May Not Be the Right Fit If:

✘ The inquiry is for price comparison only

If cost is the only deciding factor, we may not be the best match.

✘ There is no clear design or product direction

Projects without defined specifications can significantly slow down the development process.

✘ It is a one-time order with no follow-up plan

We prioritize partnerships with growth potential and continuity.

We believe the right partnerships create better products and sustainable growth.

How We Work

How We Work With Brands

Anmajy follows a clear and efficient working process,

best suited for brands that value quality, communication, and long-term collaboration.

Project Briefing & Evaluation

We begin by understanding your brand positioning, product goals, and sales plans,

evaluating design direction, craftsmanship requirements, and feasibility.

Clear communication at the start ensures smooth collaboration.

Sampling & Development

Based on tech packs, reference samples, or design concepts,

we develop samples while refining fit, materials, and construction details together.

We focus on market-ready products, not just finished samples.

Small-Batch Development

Low-MOQ production is available for product testing, collection validation,

and market launch preparation before scaling up.

Small batches are the beginning of long-term partnerships.

Bulk Production & Quality Control

Once confirmed, we proceed with stable production,

maintaining consistent quality standards, delivery schedules, and export support.

Our focus goes beyond delivery — we value reliability.

Ongoing Partnership & Optimization

For long-term partners, we support continuous product development,

process optimization, and collection expansion as brands grow.

A structured process protects both quality and efficiency.

Company Strength

-

Brand-Focused Manufacturing Experience

Anmajy is a lingerie and swimwear manufacturing partner built for brands.

We work with independent designers and established brands, supporting product development, small-batch testing, and scalable bulk production.Our team understands brand timelines, fit standards, and the level of communication required for long-term collaboration — not one-off orders.

We are structured to work with brands, not to compete on price alone.

-

Structured Workflow & Reliable Execution

From sampling to bulk production, Anmajy operates with a clear and standardized workflow.

Each stage includes defined checkpoints, documentation, and communication alignment, ensuring transparency and predictability throughout the process.This structured approach helps brands maintain control over development, reduce miscommunication, and manage production risks effectively.

-

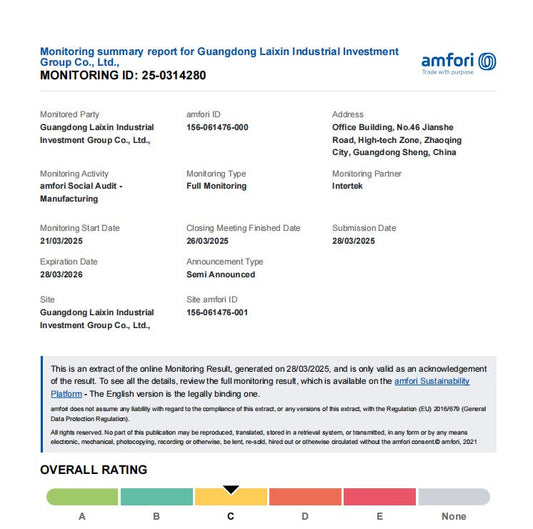

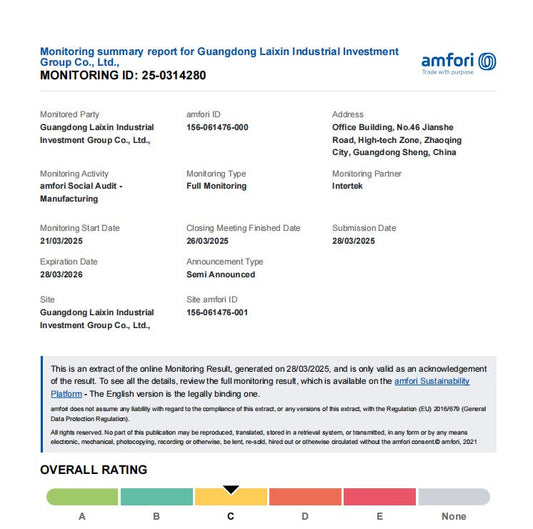

Compliance & Social Responsibility(BSCI Audited · Audit-Ready)

Anmajy is BSCI audited, with manufacturing processes aligned to international standards in labor practices, workplace safety, and social responsibility.

Compliance is not treated as a marketing label, but as part of our operational system.

For brands with compliance, audit, or retail requirements, we provide a stable, traceable, and audit-ready manufacturing environment.Audit-Ready Commitment

Compliance verification is part of our standard pre-cooperation process.

Upon request, we can provide BSCI audit documentation or support verification through authorized compliance channels.BSCI compliance at Anmajy is ongoing, not a one-time certification.

-

Consistent Quality Control

Quality control is integrated at key production stages, ensuring that bulk production aligns with approved samples in fit, construction, and finishing.

Our focus is not only on inspection results, but on maintaining consistency across repeat orders, which is essential for brands building long-term product lines.

-

Scalable Production Capacity

Anmajy offers flexible and scalable production capacity, supporting both:

Small-batch orders for product testing and market validation

Stable bulk production for growing and established brands

This allows our partners to scale responsibly without changing suppliers or compromising quality standards.

-

Suggested small line at the bottom

BSCI-audited manufacturing available for brands with compliance and long-term partnership requirements.

Daily Updates

View all-

The Role of Semi-Automation and Automation in M...

In recent years, the fusion of traditional craftsmanship and modern technology has redefined the landscape of custom apparel production. From mold manufacturing to robotic arms, semi-automated and fully automated systems...

The Role of Semi-Automation and Automation in M...

In recent years, the fusion of traditional craftsmanship and modern technology has redefined the landscape of custom apparel production. From mold manufacturing to robotic arms, semi-automated and fully automated systems...

-

Custom Underwear Molds Tailored to Client Speci...

To meet the growing demand for personalized underwear products, our factory specializes in customizing underwear molds based on client requirements, ensuring that each mold perfectly fits the product design and...

Custom Underwear Molds Tailored to Client Speci...

To meet the growing demand for personalized underwear products, our factory specializes in customizing underwear molds based on client requirements, ensuring that each mold perfectly fits the product design and...

-

In 2025, Our Factory Successfully Obtained BSCI...

2025, Our Factory Successfully Obtained BSCI Certification, Continuing to Fulfill Our Social ResponsibilityWith over 20 years of experience in the garment industry, we have always prioritized social responsibility. This year,...

In 2025, Our Factory Successfully Obtained BSCI...

2025, Our Factory Successfully Obtained BSCI Certification, Continuing to Fulfill Our Social ResponsibilityWith over 20 years of experience in the garment industry, we have always prioritized social responsibility. This year,...